ALUCORE®

ALUCORE®

ALUCORE® is an innovative aluminium composite panel consisting of two aluminium cover sheets and a honeycomb core of aluminium.

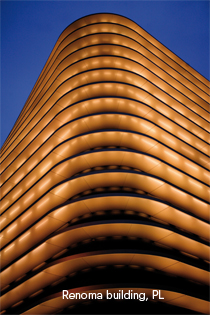

Boasting the globally recognised ALUCOBOND® trademark, ALUCORE® is also a composite material that can be used for a wide variety of applications from the transport industry to architecture, and has fantastic properties such as extraordinary flatness, a large variety of colours, and high formability.

The product’s aluminium honeycomb core gives the composite panel a high rigidity and an extremely low weight. ALUCORE® therefore has a definite advantage when it comes to projects with high demands on material stiffness – such as façade cladding or roofing where it will be exposed to an extremely high wind load, or for large self-supporting roofs.

ALUCORE® – the first lightweight panel that is a bond for life!

PRODUCT PROPERTIES

Cell size B: approx. 6.3 – 19 mm.

The cover sheets of the ALUCORE® panels consist of corrosion-resistant Peraluman alloys (AlMg) and may be used in a decorative or functional way, depending on the purpose of application

H: total thickness

d1: thickness of Al front sheet

d2: thickness of Al back sheet

| THICKNESS | ENTITY | 6MM | 10MM | 15MM | 20MM | 25MM |

|---|---|---|---|---|---|---|

| Thickness of front sheet | [mm] | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 |

| Thickness of back sheet | [mm] | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 |

| Weight | [kg/m²] | 4.7 | 5.0 | 6.7 | 7.0 | 7.3 |

ALUCORE® has the following great properties:

- A large variety of colours and perfect flatness

- Low weight and extremely high rigidity

- High formability allows design freedom to architects and planners

- Vibration damping (no additional sound damping needed)

- Simple processing using conventional tools (e.g. for folding and bending)

- Allows smooth handling on-site, even with large size panels

- Low cost for substructures and fasteners

- Short construction time, adherence to schedules, low cost

- Excellent weather resistance

Lightness meets rigidity

Sustainability

3A Composites is the parent company of ALUCOBOND® and is recognised across the globe as one of the leaders in the field of sustainability. Its reputation is spread far and wide, including among other diversified producers and raw material processing companies around the world.

The company’s unflinching commitment to sustainability – along with taking the needs of all key groups into account – enables it to make decisions of the highest economic, social, and ecological value. 3A Composites also commits to continuous self-improvement programs for environmental protection, many of which exceed government regulations.

Recycling

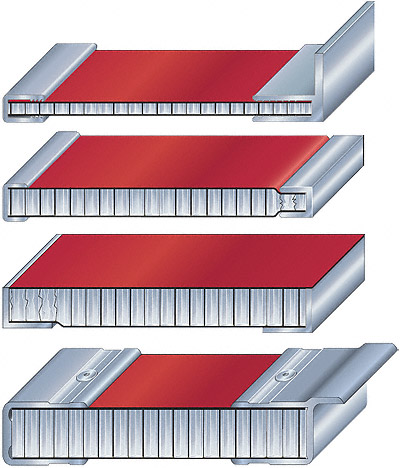

PRODUCT RANGE

| Standard colours platinum white (~ RAL 9003) and mill finish | |

|---|---|

| Thickness | 6 mm, 10 mm, 15 mm, 20 mm, 25 mm |

| Width | 1250 mm, 1500 mm |

| Length | 2500 mm, 5150 mm, 6250 mm |

| Special thickness | 5.5 – 50 mm on request |

| Special Width | up to 1500 on request |

| Special Length | On request |

| One side coil coated lacquer finish | |

|---|---|

| Thickness | 6 mm, 10 mm, 15 mm, 20 mm, 25 mm |

| Width | 1250 mm, 1500 mm |

| Length | 2000 – 9000 mm |

| Dimensional Tolerances | ||

|---|---|---|

| Thickness | ±0.2 mm | |

| Width | -0 / +4 mm | |

| Lengths | 2000 – 4000 mm | -0 / +4 mm |

| Lengths | 4001 – 9000 mm | -0 / +6 mm |

TECHNICAL DATA

| THICKNESS | CODE | UNIT | 6MM | 10MM | 15MM | 20MM | 25MM |

|---|---|---|---|---|---|---|---|

| Front Sheet | [mm] | 1.0 | |||||

| Back Sheet | [mm] | 0.5 | 0.5 | 1.0 | 1.0 | 1.0 | |

| Weight | [kg/m²] | 4.7 | 5.0 | 6.7 | 7.0 | 7.3 | |

| TECHNICAL PROPERTIES | CODE | UNIT | 6MM | 10MM | 15MM | 20MM | 25MM |

|---|---|---|---|---|---|---|---|

| Section modulus | W | [cm³/m] | 2.6 | 4.6 | 14 | 19 | 24 |

| Rigidity | E·J | [kNcm²/m] | 7.100 | 21.900 | 75.500 | 138.900 | 221.600 |

| Alloy of Aluminium Sheets | H22/H42 | EN AW-3XXX/5XXX | |||||

| Temper of Aluminium Sheets | ASTM B209-04 | EN AW-3XXX/5XXX | |||||

| Modulus of Elasticity | [N/mm²] | 70.000 | |||||

| Tensile Strength of Aluminium | [N/mm²] | Rm ≥ 125 | |||||

| 0.2 % Proof Stress | [N/mm²] | Rp0,2 ≥ 80 | |||||

| Elongation | [%] | A50 ≥ 5 | |||||

| Linear Thermal Expansion | 2.4 mm/m at 100ºC temperature difference | ||||||

| SURFACE | CODE | UNIT | 6MM | 10MM | 15MM | 20MM | 25MM |

|---|---|---|---|---|---|---|---|

| Coating | PVDF/FEVE/HDP/MILL FINISH | ||||||

| Gloos Levels | ASTM D523 | [%] | 25-80 | ||||

| Pencil Hardness | ECCA-T4 | HB-F | |||||

| ACOUSTICAL PROPERTIES | CODE | UNIT | 6MM | 10MM | 15MM | 20MM | 25MM |

|---|---|---|---|---|---|---|---|

| Sound Absorption Factor | αs | 0.05-0.07 | |||||

| Airborne sound insulation index (acc. to ISO 717-1, ISO 140-3) | 21-25 | ||||||

| THERMAL PROPERTIES | CODE | UNIT | 6MM | 10MM | 15MM | 20MM | 25MM |

|---|---|---|---|---|---|---|---|

| Thermal conductivity (regarding total thickness, incl. cover sheets) | [W/mK] | 0.95 | 1.35 | 1.35 | 2.25 | 2.70 | |

| Thermal resistance | [m²K/W] | 0.0063 | 0.0074 | 0.0084 | 0.0089 | 0.0093 | |

| Temperature Resistance | [ºC] | -40 to +80 | |||||

Wind load and permissible panel sizes

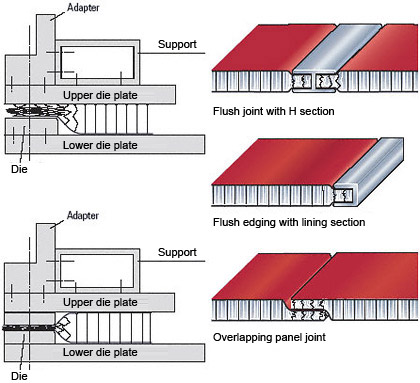

FIXING SYSTEMS

FIRE CLASSIFICATION

| Country | Test accord. to.. | Classification |

|---|---|---|

| Germany | DIN 4102 | Class B1 |

| Switzerland | VKF Fire regulations | Class 5.3 [VKF] |

| France | NF P 92-501 | M 1 |

| UK | BS 476, Part 6 BS 476, Part 7 |

Index 0 Class 1 Meets the requirement according to Class 0 of the national building regulations |

| Singapore | BS 476 Part 4 | Approved for outdoor and indoor wall cladding for any type of building without limit as to their height |

| Denmark Sweden Norway |

DS 1065.1 | Class A |

| Russia | GOST 30244-94 GOST 30402-95 GOST 12.1.044-89 GOST 12.1.044-89 |

G1 (combustibility) W1 (flammability) D2 (smoke emission) T1 (toxicity) |

INSTALLATION | MAINTENANCE | STORAGE | HANDLING GUIDELINE

| Dimensional tolerances | ||

|---|---|---|

| Thickness | ±0.2 mm | |

| Width | -0 / +2 mm | |

| Lengths | 1000 – 4000 mm | -0 / +4 mm |

| Lengths | 4001 – 8000 mm | -0 / +6 mm |

Protective foil

- To avoid residuals of glue sticking to the surface of the panels due to UV radiation, it is recommended to remove the protective foil as soon as possible after the installation.

- The protective foils and the panel surfaces must not be marked using ink (marker), adhesive tapes or stickers, as the lacquered surfaces could be damaged by solvents or plasticizers.

- Make sure to remove the protective foil as soon as possible after installation as weathering for a longer period could make the foil difficult to remove.

Cleaning and maintenance

ALUCOBOND®

Download our Alucobond processing manualStorage / Handling

- Protect ALUCORE® pallets during storage against rain, penetration of moisture and condensation.

- Only pallets of identical size should be stacked, with a maximum of 6 pallets stacked on top of each other.

- The stacking height per pallet should not exceed 2 m.

- Storage exceeding 6 months should be avoided, as it may become difficult to remove the protective foil.

- When stacking the panels nothing should be placed in between them, as this could produce marks on the panels.

PROCESSING

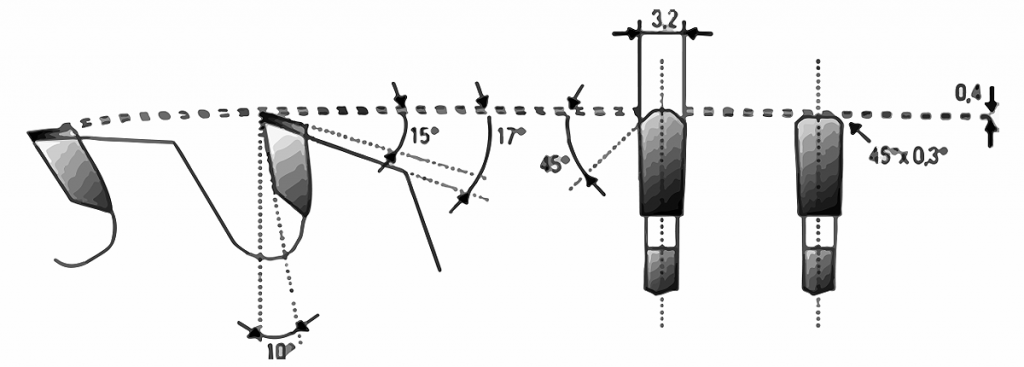

| Blade geometry | Tooth thickness approx. 2 - 4 mm, tapered to the inside to prevent jamming |

| Tooth geometry | Trapezoid tooth / flat tooth |

| Pitch t | 10 - 12 mm |

| Clearance angle α | 15° |

| Rake angle γ | 10° positive |

| Maximum cutting speed v | 5000 m/min |

| Maximum feed s | 30 m/min |

| Number of teeth | t = 72 LEUCO Code No. 18 17 24 |

| Saw blade-ø | D = 250 mm (for Holz-Her vertical panel saw 1255 ALUCORE®) |

| Number of teeth | t = 60 LEUCO Code No. 18 17 26 |

| Bore ø | D = 30 mm |

| Tooth thickness | 3.2 mm |

| Clearance angle α | 15° |

| Rake angle γ | 10 ° positive |

|

Panel thickness (mm) |

Bending radius outside (mm) |

Material gain (mm) |

Folding height min. (mm) |

|---|---|---|---|

| 6 | ~4 | 2.7 | 20 |

| 10 | ~9 | 5.0 | 25 |

| 15 | ~13 | 7.5 | 35 |

| 20 | ~16 | 8.5 | 50 |

| 25 | ~18 | 10.0 | 60 |

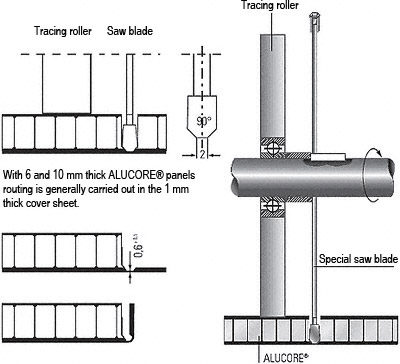

Routing and folding technique / producing corners and edges

Corners and edges can be produced simply on ALUCORE® panels using the routing and folding technique. With all versions, a groove is routed on the rear of the panel into the 1mm thick cover sheet at the front. In version 1, as with ALUCOBOND®, a cutter disk or forming cutter for V-grooves 90° is used in the appropriate width. In version 2, the core of the panel is pre-cut using special tools. The grooves can be produced with circular panel saws and CNC machining centres. Normally, folding by hand is possible. If this is not possible, we recommend the use of a folding machine.

- High-speed steel (HSS) max. cutting speed 3,000 m/min max. feed 25 m/min

- Carbide tipped (CT) cutter max. cutting speed 5,000 m/min max. feed 30 m/min

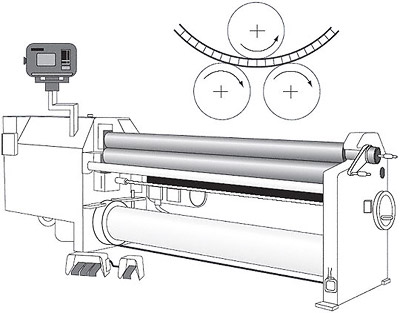

Bending with a roll bending machine

ALUCORE® honeycomb composite panels of 6mm and 10 mm thickness can be bent using three and four-roll bending machines with relatively close radii. The viscoplastic composite system enables radii to be produced from 700mm with a panel thickness of 6mm and from 1,000mm with a panel thickness of 10mm. The minimum diameter of the rolls should be 150mm. The values for adjusting the rolls have to be determined by trial. The bending rolls must be thoroughly cleaned of swarf before processing ALUCORE®. The surface should be protected from damage by affixing plastic strips of 1–2mm thickness during processing.

Step-bending with bending presses

ALUCORE® can be shaped using the step-bending process. The bending radius is determined by the stamping depth t, the stamping distance s, and the panel thickness d.

Bending with saw cuts

ALUCORE® can be bent by applying saw cuts on the rear side of the panel. The required radius ra is determined by the tooth thickness s, the wall thickness b, the panel thickness d, and the number of saw cuts. The saw cuts are carried out using the recommended saw blades. To obtain a final thickness of 1.3mm, corresponding tracing rollers are attached to the saw blades of the vertical panel saws. Principally, bending should take place in the 1mm thick cover sheet. Please ask for details.

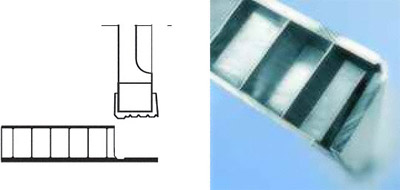

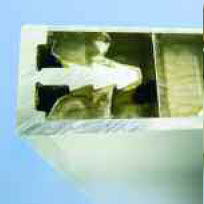

Producing edgings by folding the cover sheets

Routing the panel by means of a special saw blade After routing the panel, the honeycomb core and the rear cover sheet are cut off using a joint cutter.

After routing the panel, the honeycomb core and the rear cover sheet are cut off using a joint cutter.

Routing the panel with a cutter disk for rectangular grooves

Producing edgings by means of edge bands

Producing edgings using panel edging sections

Producing edgings using panel edging sections

- Drill material: high-speed steel (HSS)

- Tool geometry: lip angle: 100° – 140°

- Drilling without burr is possible using the following drills: Spot facing cutter with centre-point.

- Angle of twist: 30° – 45° e.g. Extreme 2TM HSS-G metal drill DIN 338 of De WALT, Idstein, Germany.

Rivets – not penetrating the panel

Rivets generally must be anchored in the 1mm thick ALUCORE® cover sheets. Sections can be attached to ALUCORE® with commercially available rivets for aluminium constructions. After drilling a blind hole of the same diameter as the rivet shank, the rivets can be anchored in the cover sheet. As a rule, rivets with stainless steel mandrel are used.

For outdoor use please note:

- For outdoor use aluminium blind rivets that have been approved for construction with a 5 mm shaft diameter and an attachment head diameter of 11 or 14 mm are used.

- Please take the thermal expansion of the panel into account (2.4 mm/m/100°C). To avoid jamming, the hole in the panel must be large enough to allow for expansion.

- With the shaft of the rivet fitting closely to the edge of the hole, the attachment head must cover over 1 mm of the area surrounding the hole.

- Multi-step drills or sleeves having corresponding diameters are used for centrically drilling holes into the panel and the substructure and for centrically fitting the rivet.

- Rivet attachment jigs are used for fitting blind rivets without jamming allowing for a tolerance of 0.3 mm. Make sure to use rivet attachment jigs and rivets from the same manufacturer, as the height of the attachment head according to DIN 7337 may vary.

- The clamping thickness results from the thickness of the material to be riveted plus an additional value of 2 mm to ensure that the closing head is perfectly formed. In accordance with this clamping thickness the corresponding shaft length is determined in the tables provided by the rivet manufacturers.

Threaded fasteners for outdoor use

For outdoor use make sure to take the thermal expansion of the panel into account. To avoid jamming, the hole diameter in the panel must allow for the expansion. Fastening without jamming is possible using fascia screws made of stainless steel with sealing washer (Fig. 1) that have been approved for construction. The screws must be suitable for the corresponding substructure (please note the information given by the manufacturer). The screws should be tightened with a torque wrench or screwdriver so that the sealing washer is placed on the panel for sealing the bore hole without exerting pressure to the panel. Multi-step drills or sleeves having corresponding diameters are used for centrically drilling holes into the panel and the substructure and for centrically fitting the rivet. Important: Make sure to remove the protective foil prior to screwing.Examples for threaded fasteners

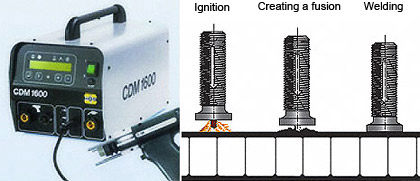

Stud welding with tip ignition on mill-finished ALUCORE® surfaces Process:

- The capacitor battery is charged.

- A spring in the welding gun moves the stud (with tip) towards the work-piece.

- The tip comes into contact with the work-piece and thereby closes the circuit. The rapidly increasing current causes the ignition tip to melt instantaneously, thus initiating the electric arc.

- Stud and work-piece are welded together.

- When the stud touches the work-piece the electric arc is extinguished, the fusion zones on stud and work-piece are joined and solidify.

Tapes/Velcro tapes

Double-sided tapes (such as the 3M-VHB high capacity jointing systems) can be used for the above applications with low tensile or transversal strength requirements. Velcro tapes are available for detachable joints, for example SCOTCHMATE or tapes marketed under the Dual Lock trademark.Adhesive sealing compounds

For high-strength and elastic connections we recommend the following one-component adhesive sealing compound: Sika Bond-T2 (polyurethane base). For outdoor use, this adhesive can be used for fastening parts of minor static importance.Metal adhesives/Universal adhesives

For indoor use, trade fair/exhibition stand structures, machines, etc. most metal or universal a dhesives are suitable.Important:

Please observe the manufacturer’s instructions regarding the application and use of adhesives/tapes. Laminating of ALUCORE® panels to other materials may result in deformation of the laminates (differing expansion/bimetal effect).ALUCORE® over lacquering procedure:

- Pre-cleaning of the panels using methylated spirit

- Grinding the surfaces with wet abrasive paper (grain size 360)

- Removing grinding dust with a lint free cloth moistened with spirit

- For the topcoat, please follow the instructions of the topcoat supplier.

Please note:

- The maximum permissible temperature of the material (ALUCORE® panels) must not exceed 70°C when applying fast-drying methods. During the drying process at high temperatures the ALUCORE® panels must be positioned or stored with great care to prevent deforming.

- ALUCORE® cut edges should not be in contact with organic solvents for a prolonged period of time to avoid weakening the bond.

- ALUCORE® panels lacquered or over lacquered at a later stage should not be bent or folded. The lacquer in the bends or folds may be damaged due to the low elasticity of the topcoat.