UNDERSTANDING FIRE RETARDANCY

- Lateral and Vertical spread of fire

- Smoke emission

- Droplets

- Self-extinction of fire on the ACM

- Ideally recommended mix and density of non- combustible content in the core (not less than 70%).

- Appropriate certifications from a credible 3rd party authority. Not sufficient to have mere test reports from samples provided by the applicant.

- Should be fixed using the recommended systems.

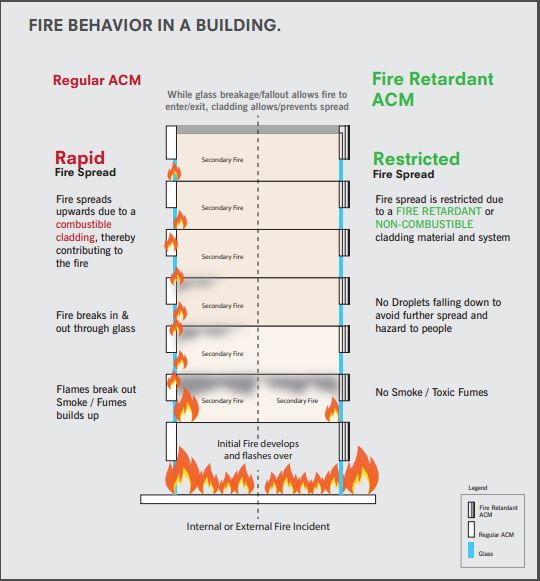

FIRE BEHAVIOUR IN A BUILDING

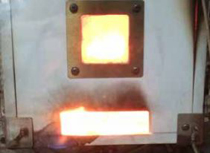

The Illustration shows the fire propagation in case of fire in a building:

FIRE RETARDANCY VIDEO

FIRE RETARDANCY NEWSLETTER

ALUCOBOND® and Fire Retardancy

Keep up to date with the latest news and industry developments regarding Fire Retardancy and Safety with our newsletter. Staying abreast of current regulations and developments is essential for working successfully on new construction and design projects.

Subscribe here

FIRE RETARDANCY PRESENTATION

ALUCOBOND® Fire Retardancy Presentation

Fire – An ALUCOBOND® PerspectiveFIRE RETARDANCY BROCHURE

ALUCOBOND® Fire

Due to stricter global regulations and the evermore demanding requirements of modern architecture, choosing the right fire retardancy products and systems is essential. Download our in-depth brochure to find out how ALUCOBOND* meets these challenges through experience and innovation to lead the market.

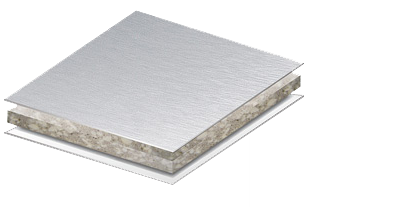

ALUCOBOND® A2

Technical Data Sheet

| THICKNESS | STANDARDS | UNIT | 3MM | 4MM | |

|---|---|---|---|---|---|

| Thickness of Aluminium Layers | 0.5 | 0.5 | |||

| Weight | [kg/m²] | 5.9 | 7.6 | ||

| Width | [mm] | 1250 / 1500 | 1250 / 1500 |

| TECHNICAL PROPERTIES | STANDARDS | UNIT | 3MM | 4MM | |

|---|---|---|---|---|---|

| Section modulus | W | DIN 53293 | [cm³/m] | 1.25 | 1.75 |

| Rigidity | E·J | DIN 53293 | [kNcm²/m] | 1250 | 2400 |

| Alloy / Temper of Aluminium Layers | EN 573-3 / EN 515 | EN AW 5005A (AIMg1) H22/H42 | EN AW 5005A (AIMg1) H22/H42 | ||

| Modulus of Elasticity | EN 1999 1-1 | [N/mm²] | 70.000 | 70.000 | |

| Tensile Strength of Aluminium | EN 485-2 | [N/mm²] | Rm ≥ 130 | Rm ≥ 130 | |

| 0.2 % Proof Stress | EN 485-2 | [N/mm²] | Rp0,2 ≥ 90 | Rp0,2 ≥ 90 | |

| Elongation | EN 485-2 | [%] | A50 ≥ 5 | A50 ≥ 5 | |

| Linear Thermal Expansion | EN 1999 1-1 | 2.4 mm/m at 100ºC temperature difference | 2.4 mm/m at 100ºC temperature difference |

| CORE | STANDARDS | UNIT | 3MM | 4MM | |

|---|---|---|---|---|---|

| Mineral compound, polymer bonded |

| SURFACE | STANDARDS | UNIT | 3MM | 4MM | |

|---|---|---|---|---|---|

| Lacquering | Coil Coating Fluorocarbon based (e.g. PVDF) | Coil Coating Fluorocarbon based (e.g. PVDF) | |||

| Gloss (initial value) | EN 13523-2 | [%] | 30-80 | 30-80 | |

| Pencil Hardness | EN 13523-4 | HB-F | HB-F |

| ACOUSTICAL PROPERTIES | STANDARDS | UNIT | 3MM | 4MM | |

|---|---|---|---|---|---|

| Sound Absorption Factor | αs | ISO 354 | 0.5 | 0.5 | |

| Sound Transmission Loss | Rw | ISO/DIS 717-1, EN ISO 140-3 | [dB] | 27 | 27 |

| Loss Factor | d | EN ISO 6721 Frequency range 100-3200 Hz | 0.004 | 0.005 |

| THERMAL | STANDARDS | UNIT | 3MM | 4MM | |

|---|---|---|---|---|---|

| Thermal Resistance | R | DIN 52612 | [m²K/W] | 0.002 | 0.002 |

| Thermal conductivity | λ | DIN 52612 | [W/mK] | 1.99 | 1.77 |

| Heat Transition Coefficient | U | DIN 52612 | [W/m²K] | 5.83 | 5.80 |

| Temperature Resistance | [ºC] | -50 to +80 | -50 to +80 |

Fire Classification

| Country | Test accord.to | Classification |

|---|---|---|

| Australia | AS ISO 9705 AS 1530.3 Indices EN 13501-1 | Group 1 material SMOGR A 0.630 m2 / s2 0 (ignitibility) 0 (flame spread) 0 (heat evolved) 0-1 (smoke development) A2-s1, d0 |

| China | GB 8624-2012 | Class A (A2- s1,d0, t0) |

| EU | EN 13501-1 | Class A2-s1, d0 |

| Germany | EN 1187 (method 1) / DIN 4102-7 | Passed |

| Great Britain England / Wales / Scotland | BR 135 BS 8414 part 1 & 2 | met the performance criteria Passed |

| Malaysia | BS 8414-1 BS 476, Part 6 BS 476, Part 7 Approved for outdoor wall cladding of any type of building without height limit | Passed Class 0 Class 1 |

| Poland | EN 13501-1 BS 476, Part 6&7 (Core Exposed) NFPA 285 Approved for outdoor wall cladding of any type of building without height limit | Class A2-s1, d0 |

| Russia | GOST 30244-94 GOST 30402-95 GOST 12.1.044-89 GOST 12.1.044-89 | G1 (combustibility) W1 (flammability) D1 (smoke development) T1 (toxicity) |

| Singapore | EN 13501-1 BS 476, Part 6&7 (Core Exposed) NFPA 285 Approved for outdoor wall cladding of any type of building without height limit | Class A2, s1, d0 Passed Passed |

| Switzerland | VKF | RF1 |

| UAE | NFPA 285 EN 13501-1 ASTM E84 | Passed Class A2-s1, d0 Class A |

ALUCOBOND® PLUS

Technical Data Sheet

| THICKNESS | STANDARDS | UNIT | 3MM | 4MM | |

|---|---|---|---|---|---|

| Thickness of Aluminium Layers | [mm] | 0.5 | |||

| Weight | [kg/m²] | 5.9 | 7.6 | ||

| Width | [mm] | 1000 / 1250 / 1500 (1575 / 1750) | |||

| TECHNICAL PROPERTIES | |||||

| Section modulus | W | DIN 53293 | [cm³/m] | 1.25 | 1.75 |

| Rigidity | E·J | DIN 53293 | [kNcm²/m] | 1250 | 2400 |

| Alloy / Temper of Aluminium Layers | EN 573-3 EN 515 | EN AW 5005A (AIMg1) H22 / H42 | |||

| Modulus of Elasticity | EN 1999 1-1 | [N/mm²] | 70.000 | ||

| Tensile Strength of Aluminium | EN 485-2 | [N/mm²] | Rm ≥ 130 | ||

| 0.2 % Proof Stress | EN 485-2 | [N/mm²] | Rp0,2 ≥ 90 | ||

| Elongation | EN 485-2 | [%] | A50 ≥ 5 | ||

| Linear Thermal Expansion | EN 1999 1-1 | 2,4 mm/m at 100ºC temperature difference | |||

| CORE | |||||

| Mineral filled polymer | |||||

| SURFACE | |||||

| Lacquering | Coil Coating Fluorocarbon (e.g. PVDF) | ||||

| Gloss (initial value) | EN 13523-2 | [%] | 30-80 | ||

| Pencil Hardness | EN 13523-4 | HB-F | |||

| ACOUSTICAL PROPERTIES | |||||

| Sound Absorption Factor | αs | ISO 354 | 0.05 | ||

| Sound Transmission Loss | Rw | ISO 717-1 | [dB] | ≥ 25 | |

| THERMAL PROPERTIES | |||||

| Thermal Resistance | R | DIN 52612 | [m²K/W] | 0.007 | 0.009 |

| Thermal conductivity | λ | DIN 52612 | [W/mK] | 0.49 | 0.44 |

| Heat transition coefficient | U | DIN 52612 | [W/m²K | 5.68 | 5.58 |

| Temperature Resistance | [ºC] | -50 to +80 | |||

Fire Classification

| Country | Test accord. to … | Classification |

|---|---|---|

| Australia | AS ISO 9705 AS 1530.3 Indices EN 13501-1 | Group 1 material SMOGR A 1.385 m2 / s2 0 (ignitibility) 0 (flame spread) 0 (heat evolved) 0-1 (smoke development) B-s1, d0 |

| China | GB 8624-2012 | Class B1 (B- s1,d0, t0) |

| EU | EN 13501-1 | Class B-s1, d0 |

| Germany | EN 1187 (method 1) / DIN 4102-7 | passed |

| Great Britain England / Wales / Scotland | BS 476, Part 6 & 7 BR 135 BS 8414 part 1 & 2 | Class 0 met the performance criteria Passed |

| Malaysia | BS 8414-1 BS 476, Part 6 BS 476, Part 7 Approved for outdoor wall cladding of any type of building without height limit | Passed Class 0 Class 1 |

| Poland | PN-90/B-02867 | NRO |

| Russia | GOST 30244-94 GOST 30402-95 GOST 12.1.044-89 GOST 12.1.044-89 | G1 (combustibility) W1 (flammability) D1 (smoke development) T1 (toxicity) |

| Singapore | EN 13501-1 BS 476, Part 6&7 NFPA 285 Approved for outdoor wall cladding of any type of building without height limit | Class B-s1, d0 Passed Passed |

| Switzerland | VKF | RF2 |

| UAE | NFPA 285 EN 13501-1 ASTM E84 | Passed Class B-s1, d0 Class A |

| USA | ASTM E84 NFPA 285 | Class A Passed |

| Country | Large fire testing | Classification |

|---|---|---|

| Austria | ÖNORM B 3800-5 | passed |

| France | Lepir 2 | passed |

| Hungary | MSZ 14800-6 | passed |

| Great Britain | BS 8414 part 1 & 2 | passed |

| Poland | According to ITB guidelines | passed |

| Russia | GOST 31251 | passed |

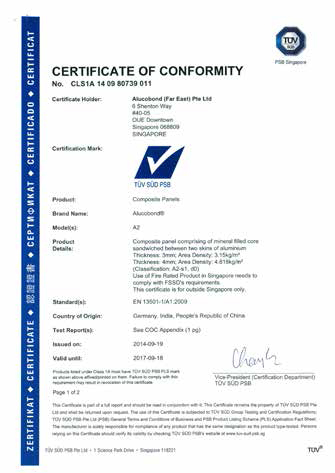

CERTIFICATIONS

In order to ensure the true capability of the manufacturer and their products, one should insist on a Certification from a trusted third party.

Any reputed third party certification organization will:

- Investigate the manufacturing process, QA process, test reports / documentation.

- Inspect the manufacturing facilities periodically.

- Select production samples randomly for later testing.

- Awards certificate of conformity if they find everything in order.

- Renew certificate only if all of the above are consistently achieved at satisfactory levels.

ALUCOBOND ® products from Germany, China and India are Class 1A Certified which means not only the products but also the processes are inspected on periodic intervals by TUV SUD, which is an internationally known and trusted independent certification organization.

MINERAL CALCULATOR

Download our Mineral Calculator by clicking the link below.

COMMONLY REQUESTED FIRE TESTS

ASTM E-84

BS 476 – Part 6&7

EN 13501-1

NFPA 285