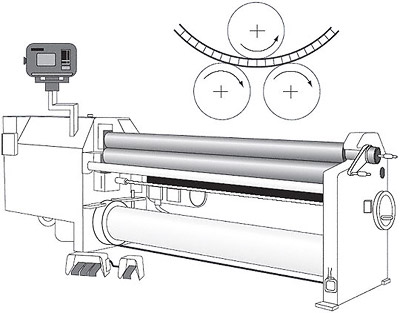

Bending with a roll bending machine

ALUCORE® honeycomb composite panels of 6mm and 10 mm thickness can be bent using three and four-roll bending machines with relatively close radii. The viscoplastic composite system enables radii to be produced from 700mm with a panel thickness of 6mm and from 1,000mm with a panel thickness of 10mm. The minimum diameter of the rolls should be 150mm. The values for adjusting the rolls have to be determined by trial. The bending rolls must be thoroughly cleaned of swarf before processing ALUCORE®. The surface should be protected from damage by affixing plastic strips of 1–2mm thickness during processing.

Step-bending with bending presses

ALUCORE® can be shaped using the step-bending process. The bending radius is determined by the stamping depth t, the stamping distance s, and the panel thickness d.

Bending with saw cuts

ALUCORE® can be bent by applying saw cuts on the rear side of the panel. The required radius ra is determined by the tooth thickness s, the wall thickness b, the panel thickness d, and the number of saw cuts. The saw cuts are carried out using the recommended saw blades. To obtain a final thickness of 1.3mm, corresponding tracing rollers are attached to the saw blades of the vertical panel saws. Principally, bending should take place in the 1mm thick cover sheet. Please ask for details.